Today, as human beings are responsible and aware of environmental endangerment and seek for better practices, green zoning and sustainable business have gained increased acceptance. Such business owners put into practice whatever little they can to copy the idea of wastage reduction and carbon footprint cutting on Earth and are really into following examples set by others across our globe.

Recycling of scrap metal, which is a cornerstone of these efforts, is a way of transforming valuable materials which would otherwise be thrown away. Pavlo has been collecting batteries for 10 years in concrete and asphalt and then recycles the acid to be purified and the lead to be melted into new batteries as well as the extrusion of internally stock multiple components.

Being Aone Copper, we are amazing in giving scrap metals a new life through a systematic and environmental-friendly recycling process. Our cutting-edge approach empowers us to gather, process, and reuse metals, thus playing a role in substantial raw material acquisition for many industries as well as minimizing the environmental impact. This article will provide an in-depth look at our recycling process, the benefits of scrap metal recycling, and how Aone Copper is making a difference in promoting sustainability.

Table of Contents

ToggleThe Importance of Scrap Metal Recycling

Metal recycling is a very important part of the whole world’s attempt to increase sustainability and decrease the load of natural resources. Metals such as steel, aluminum, copper and iron are the so-called resources that humanity gets from the Earth through mining. Besides removing the earth’s resources by its process, mining also pollutes the environment through such actions as deforestation, soil erosion and habitat loss.

One of the most important environmental benefits of recycling scrap metal is that we can reduce virgin metal extraction and the associated undesirable environmental impacts from mining. Besides, the recycling of scrap metal has several other main benefits including

- Environmental Protection: Recycling metal reduces the need for new materials. For example, recycled metals can be used to make new products without the need for metal mining. This helps protect the environment and natural resources.

- Energy efficient: More importantly, recycling metals requires much less energy than it does to produce metals from raw ore. Take aluminum, for example. Recycling aluminum can save 95 percent of the amount of energy needed to extract and melt new aluminum from bauxite liquor. Metal recycling also saves 60 percent of the energy consumption in mining and metallurgy.

- Emission Reduction: Metal recycling helps reduce emissions by reducing the energy required for production. This in turn helps to mitigate climate change by reducing the carbon footprint of the steel industry.

- Waste reduction: Metals are non-biodegradable, and when they end up in landfills, they take up valuable space and can leach harmful chemicals into the soil and water. Recycling old products prevents this waste from ending up in landfills, reducing the burden on the waste management system.

- Economic benefits: Recycling creates jobs and boosts the local economy. The industrial metals market is a rapidly growing industry that serves a variety of sectors, including manufacturing, construction and automotive. Additionally, recycled steel is often less expensive than freshly mined steel, saving both companies and consumers money.

Our Scrap Metal Recycling Process: From Waste to Resource

At Aone Copper, we have developed a robust and efficient recycling process that ensures scrap metal is transformed into valuable resources. Our process is designed to maximize resource recovery while minimizing environmental impact. Here’s how it works:

1. Collection and Transportation of Scrap Metal

The first step in the recycling process is to consolidate the scrap metal. Metal waste from construction sites, factories, homes, and demolition are the key sources. We cooperate effectively with different local companies, clients from industries, and private individuals and get the metal waste in a sustainable and timely way.

To achieve the task, our team goes for a mix of methods: onsite pick-up, drop-off locations, as well as working together with local recycling centers. We make sure to follow the local rules and the industry’s best practices both in relation to the selection process and the subsequent handling and use of scrap metal.

After the collection has been finished, the metal is brought to our recycling plant for the sorting and processing.

2. Sorting and Classification of Metals

For recycling, the scrap metal has to be sorted and categorized according to its type and composition. It should be divided primarily into metals that are Ferric and those that are Non-Ferric. Hence, typically it is said that types of metals are primarily classified in two categories- ferrous and non-ferrous metals.

- Ferrous metals: These include steel and iron, which are magnetic and widely used in industries like construction, automotive, and machinery manufacturing.

- Non-ferrous metals: These include aluminum, copper, brass, and zinc, which are more resistant to corrosion and are often used in electrical wiring, plumbing, and aerospace applications.

One such good method is the use of modern, most innovative metal separation methods that make all varieties of metal worthless. We use the manual sorting method along with magnets and eddy current separators, which are machines using magnetic field induction forces for detecting metals with speed and accuracy. The proper type of sorting is an important determinant that will ensure that the recycling procedure will produce high-quality material consistent with the set standards of industry.

3. Cleaning and Preparation for Processing

Immediately after separating, the scrap metal is cleaned in such a way that it is not contaminated with any substance like plastic, paint, rubber or other non-metallic materials. It is important to take this step in order to get pure and non-harmful recycled metal in the end.

Clean-up is followed by the division of the metal for its processing through the use of a saw or shredder. The larger the surface area, the easier is the melting process of the metal in the following phase of recycling.

4. Melting and Purification

The metal is damaged and crushed, it is sent to the stoves. Furnaces of each kind of metal should be heat at a specific temperature, and our factory has furnaces for any metal. The melting metal is melted, so type product can be poured out again and the rest of the impurities and oil can be removed easily.

We, on this stage, also purify the metal further. Enrichment procedures, e.g. electrolysis, chemicals and magnetic attraction, guarantee that the recycled metal is the best. Enrichment is mainly necessary partly for non-ferrous materials like copper and aluminum, materials which are used in sensitive applications such as electronics and aerospace manufacturing.

5. Casting and Solidification

Once the metal is purified, it will be ready for pouring into molds or for cooling into solid blocks called ingots. The ingots are easy to transport and store until needed by manufacturers. Ingots may come in definite shape and size that depends on the changed needs of the metal as applied to the different industries.

A good example is the case where the metal might undergo additional processes like rolling or extrusion for the creation of a specific product. This action ensures that the metal can be applied in the production of any items that require it in diversified industrial sectors.

6. Distribution to Manufacturers

The last step in our recycling process is when we sell the recycled metal to the manufacturers, who then make new items from it. Recycled metals are in demand within an industry scope as wide as:

- Automotive: During the vehicle-making process, it recycles the steel and aluminum materials used instead of newly mined materials.

- Construction: Steel and copper can be recovered from building materials, pipes, and electrical wiring.

- Electronics: Non-ferrous metals, including copper, aluminum, and gold, which have great quantities in the production of electronics, enable these metals to be recycled back to the production cycle to help limit some of the detrimental effects electronic waste has on the environment.

- Consumer Goods: Nearly every household appliance, furniture, and packaging is recycled into metal.

By providing manufacturers with high-quality recycled metal, Aone Copper helps reduce the environmental impact of their production processes and supports the development of a more sustainable economy.

How Scrap Metal Recycling Contributes to a Circular Economy

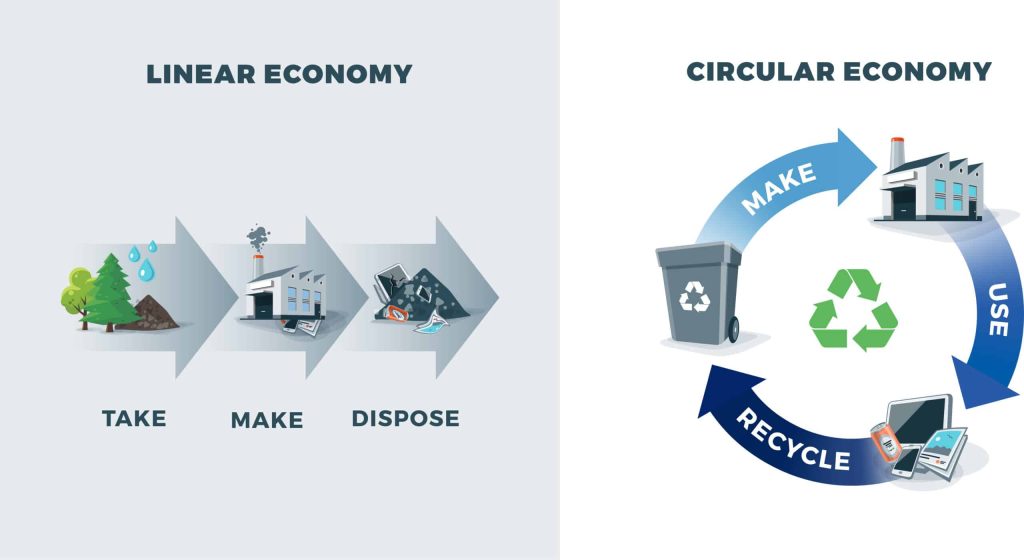

The idea of the circular economy is deployed by businesses deploying the use of resources for the longest time possible, with goods and materials being reused, restored, and recycled at the end of their life cycles. Copper recycling constitutes an essential part of the circular economy, as it enables ongoing adaptation to be made from the residual material, by diversion and recycling of metal and other material wastes.

In a traditional linear economy, raw materials are extracted and used to produce products, which, once the products reach the end of their useful life, are then discarded in landfills. This model resultantly is not sustainable as it brings about the depletion of natural resources and the build-up of waste.

On the other hand, a circular economy is aimed at the closure of the loop to keep the materials available for re-cycling as long as possible. Through recycling of scrap metal, we can cut down on the mining for resources that would be otherwise new, thus, reduce waste and the environmental effect of production and consumption.

Partner with Aone Copper for Sustainable Metal Recycling

We, Aone Copper, remain committed to the environment while delivering our promise of scrupulously recycling the metal waste. We have invented a procedure that empowers us to use the vastness of resources available while keeping the environmental footprint at the minimum level. Thus, we make our process a savior for business and individuals looking forward to reducing their carbon footprint and therefore adding towards a greener future.

Whether you are a construction company that needs to recycle large quantities of scrap metal, a manufacturer who wants to find high-quality recycled materials, or an individual with metal waste to dispose of responsibly, we have the expertise and resources to meet your needs. Through our partnership with Aone Copper, not only will you contribute to recycling scrap metal into prized resources but, importantly, also to the realization of Earth’s sustainable future.

Final Thoughts

Scrap metal recycling not only decreases waste but also correlates with other environmental benefits. Thus it is a key point of a new line of approach to doing business and as a result, it is the magna cum laude of the business world in which scrap recycling represents. Recycling is a necessary condition for the process of regaining metal and is a solution to environmental pollution. Besides, recycling is a process that yields almost no waste and is cheap, efficient, and green .